Seamless steel pipes are steel tubes manufactured without a welded seam, providing higher structural integrity, pressure resistance, and uniform mechanical performance than welded alternatives. For industries requiring safety, durability, and precision, seamless steel pipes—often referred to as seamless steel tube or SMLS pipe—are a core material choice rather than an optional upgrade.

As a professional seamless steel pipe manufacturer, HXH Steel supplies seamless solutions designed to meet international standards and real-world operating demands.

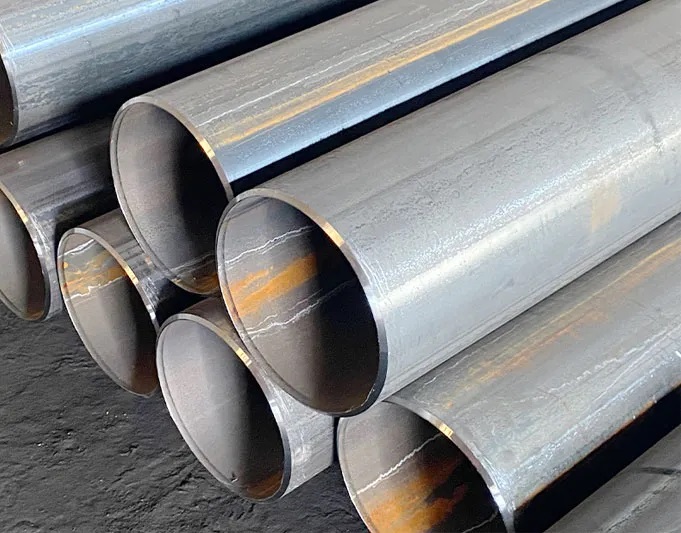

A seamless steel pipe is a hollow steel product formed from a solid billet rather than welded from plate or strip. Because the pipe body has no longitudinal or spiral weld, stress is evenly distributed across the entire circumference.

This structural continuity makes seamless steel pipes suitable for:

High-pressure fluid transmission

High-temperature environments

Cyclic load and fatigue-sensitive systems

The manufacturing method directly determines dimensional accuracy, surface quality, and mechanical performance.

Billet Heating – Solid round steel billets are heated to high temperatures.

Piercing – A mandrel pierces the billet to create a hollow shell.

Rolling or Drawing – The hollow shell is hot rolled, cold rolled, or cold drawn to achieve target dimensions.

Sizing & Straightening – Diameter and wall thickness are precisely controlled.

Heat Treatment – Normalizing, quenching, or tempering improves mechanical properties.

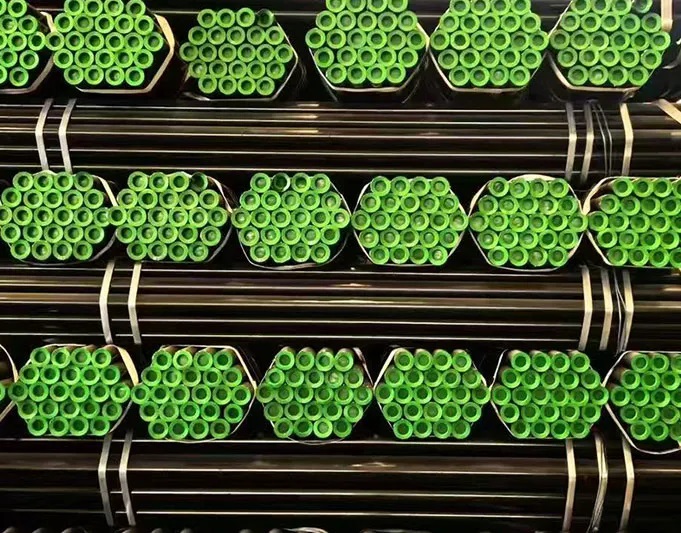

Finishing & Inspection – Pipes are cut, surface-treated, and tested.

Cold-drawn seamless steel tubes are commonly used where tight tolerances and smooth internal surfaces are required.

Seamless steel pipes can be classified by process, shape, and application.

Hot-Rolled Seamless Steel Pipe – For structural and pressure applications

Cold-Rolled Seamless Steel Tube – Improved surface finish

Cold-Drawn Seamless Steel Tube – High precision and strength

Round seamless steel pipes

Special-shaped seamless tubes

Pressure pipelines

Mechanical tubing

Boiler and heat exchanger tubes

Seamless steel pipes demonstrate balanced and predictable mechanical performance:

High tensile and yield strength

Excellent elongation and plasticity

Strong fatigue resistance under cyclic loads

Stable performance at elevated temperatures

These properties are especially critical in applications such as hydraulic cylinders, boilers, and petrochemical pipelines.

Seamless steel pipes are widely applied across critical industries:

Oil & Gas – drilling, casing, transmission pipelines

Power Generation – boilers, superheaters, steam pipes

Mechanical Manufacturing – shafts, sleeves, hydraulic systems

Chemical & Petrochemical – corrosive and high-temperature media

Automotive & Heavy Equipment – structural and load-bearing components

Their performance consistency supports long-term operational safety.

How quality is verified matters as much as how pipes are produced.

Seamless steel pipes undergo strict inspection to meet ASTM, ASME, API, and EN standards:

Chemical composition analysis

Mechanical testing (tensile, yield, elongation)

Hydrostatic or pressure testing

Ultrasonic or eddy current testing

Dimensional and surface inspection

A qualified seamless steel pipe manufacturer provides full material traceability and test certification.

A reliable supplier is defined by more than price.

Key factors to evaluate:

Compliance with international standards

Consistent raw material sourcing

In-house or verified third-party testing

Export experience and documentation accuracy

Technical support beyond delivery

As a professional seamless steel pipe manufacturer, HXH Steel focuses on stable quality, specification accuracy, and application-based material recommendations. Backed by experienced technical teams and strict quality control systems, we support customers in selecting the right seamless steel pipe solutions for their specific operating conditions. Contact us to discuss your project requirements and receive professional guidance, technical support, and competitive supply solutions tailored to your needs.

Yes. Seamless steel pipes are widely used in boilers, heat exchangers, and power plants because their uniform structure maintains mechanical stability under high temperatures and thermal cycling.

Seamless steel pipes are typically manufactured in accordance with ASTM, ASME, API, EN, and DIN standards, depending on application and regional requirements.

Yes. Seamless steel pipes can be fully customized to meet specific project and application requirements. At HXH Steel, we offer comprehensive custom processing services, including cut-to-length, end beveling, and threading to ensure compatibility with installation and connection standards. We also provide heat treatment services such as normalizing and tempering to optimize mechanical properties for pressure, temperature, or load-bearing conditions.